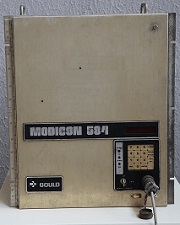

Modicon 584A

584A Inside

584A

The Modicon 584A PLC's were very powerful for their time. The first ones in Australia had ferrite memory. I installed the first one in Western Australia, complete with solid state memory, in 1981. This was at the Vanaduim plant at Wundowie. I think it had 8kb of memory and we configured it with 500 series remote I/O. These were also installed at Worsley Alumina in 1983 and ran for many years with 200 series I/O. These were top of the range from 1979 through 1983, when the 584L became available.

Built into the door was the (RAP) "Register Access Panel". This had a membrane keypad and a single line display. Using this it was possible to view and/or change data values in memory addresses. This was an extremely handy fault finding tool.

Opening the door revealed the insides. A large power supply, the circuit boards that made it all happen. The I/O processor, memory and the CPU boards all connected by multiple ribbon cables. The RAP was also connected by another ribbon.

Programming was in ladder and we used a P190 programming panel to enter the program and for diagnostics. By current standards the 584 and the P190 were very primitive, but they controlled the Western Aistralian mining industry for many years. These were the first to offer full dual redundant Hot-Standby systems, the first of which were installed at Worsley Alumina in 1982/4.

These generally used 200 series I/O, introduced with the 184 series controllers, which was designed to last forever, which could be the case. Some of the original 200 series modules were still running in W.A. in 2022. The system allowed hot swap of modules without the need to shutdown the processor.

Programming tools improved and several PC based packages were available eventually for DOS and later Windows.